Form Follows Function.

If a lively debate is ever sought amongst artists then the moot could be 'craft precedes art'. Likewise architects get all fired up when 'form follows function' gets bandied around -well that is the purpose of this article.

It was American architect Louis Sullivan who made the phrase famous but what Sullivan actually said was 'form ever follows function', but the simpler phrase is the one usually remembered. He felt pretty strongly about it and also said it was a "rule that shall permit of no exception".

Linking the relationship between the form of an object and its intended purpose is a good idea for designers and architects, but it is not always by itself a complete design solution.

In the1900's Sullivan built tall steel skyscrapers in Chicago at the time of great changes in technology and economic change leaving behind the established styles of the past. Frank Lloyd Wright, Sullivan's assistant adopted the same principle but said 'Form follows function - that has been misunderstood. Form and function should be one, joined in a spiritual union'.

The Modernists, Le Corbusier, Walter Gropius and Mies Van der Rohe went another step further and stated that 'ornament is a crime' and between 1945 and 1984 Modernism seemed to be the only respected architectural form of the profession. The resulting structures tended to be simpler, taller, and lighter but looked honest and even naked alongside their older neighbors.

In the mid-1930's Philip Johnson said, "Where form comes from I don't know, but it has nothing at all to do with the functional or sociological aspects of our architecture". So although the stark reality is still there we have seen some interesting buildings lately because the profession now seems to view architecture more as a matter of aesthetics than form. Recently five of Australias leading architects were asked which were the worlds and Australias most notable buildings. Some mentioned Eero Saariens TWA airport terminal, some St Peters in Rome, but four of them included Jorn Utzons Sydney Opera House. This was quite remarkable as it was the roof that provided the architecture. Not just a form of function but an essential part of the design.

Recently five of Australias leading architects were asked which were the worlds and Australias most notable buildings. Some mentioned Eero Saariens TWA airport terminal, some St Peters in Rome, but four of them included Jorn Utzons Sydney Opera House. This was quite remarkable as it was the roof that provided the architecture. Not just a form of function but an essential part of the design.

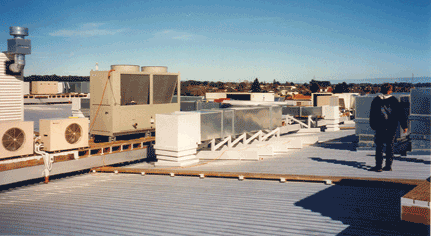

Historically designers placed a plant-room on the top of a building as the central location for HEVAC equipment and although smaller individual units are now in fashion there must be a better way than what is being done at present.

I do not think that all that equipment stuck up on a roof looks pretty - do you? So why do we have to put up with it?

It seems nobody is to blame. The installer only did what the contractor asked him, the contractor only did what the designer asked him, the designer only did what the owner asked him.

An industrial building does not have to compete with the Sydney Opera House but it can look better than this.

There is another problem though, probably more important than aesthetics.

The prime function of a roof is to keep the water out but this is getting progressively harder as the assumption is made that anyone can walk anywhere on a roof! The number of leaking penetrations is disproportionate.

Some say that the gauge of the metal is too thin. Well, like your BMW, the metal has been getting thinner for a while now but it has also gone up in strength. All our roofing profiles are tested for their resistance to point load. Steel is strong in tension but weak in compression. The intermediate span is 50% greater than the end span only because of the continuity it provides. When you cut a hole in a roof, the intermediate span becomes an end span!

That means extra support is required for the roof in front and behind of the hole to allow the roof cladding to perform as it was designed. When you cut a hole in the roof the water has to be diverted. If the hole is at the bottom of the roof the catchment is considerable and special provision must be made (see NZMRM Code of Practice 6.1.4.)

There are many ways to flash a penetration and you do not have to suffer an ugly final appearance (read NZMRM Code of Practice section 6.0.)

When ladder access to a roof is required the 'step-off' place is always at an end span and much damage occurs at this point. Internal access is always desirable but costs moreIn many countries a log book is kept of everyone who goes on the roof. No one is allowed on the roof without permission, no matter who they are!

The roofing industry is concerned about the damage that is occurring to metal roofs by the installation and servicing of air-conditioning equipment mounted on metal roofing.

We believe that much of this damage could be avoided if there was more information available to designers and greater detailing for the installers.

We believe that one of the purposes of the pending Licensing of Building Practitioners, including designers, is that everyone should take responsibility for their part in the building process.

That means the designer must design where the outlets are to be positioned on the roof, and draw the details so that they comply with the NZ Building Code and the NZ Metal Roofing Manufacturers Code of Practice. It also means that the end span must be reduced to 2/3rds of the intermediate.

All metal roofs are designed to support 1.1kN so if you are over 100 kg that means you should not be up there!

We believe that this means the installer must transport any units over a designed walkway so that the roof is not damaged.

If any of the units need regular maintenance a walkway should be designed and provided for.

Stuart Thomson is a Building Consultant to NZ Metal Roofing Manufacturers Inc., Roofing Association of NZ and NZ Steel.

Some facts:

- Just about all roofs can be walked on in the pan - but not on the ribs.

- The roof will not support air-conditioning units unless there is a supporting structure underneath it.

- If the ribs are dented, they cannot be satisfactorily repaired and the sheet should be replaced.

- If there is damage or ponding the warranty is voided.

- Run-off over, or condensate from, copper pipes must not discharge onto metal roofs.

- Leachate from CCA treated Pinus or hardwoods must not discharge onto metal roofs.

- Any timber, painted or otherwise, supporting aircon units must be separated by butyl rubber on top of the rib -not on the pan.

- All boot flashings must be placed at 450 to the roof to avoid ponding.

- All boot flashings must have one entry only - or be designed as per the drawings shown in this article.

- Silicone is not a substitute for a flashing.

- Unwashed areas are not covered by any warranty.